what we’ve done

our projects

tank Mixing

Comparing Apples to Apples: Objective Comparison Leads to Optimal Solution

The City of Columbus, Ohio, took a proactive approach in evaluating the best mixer solution for their finished water storage facilities. Initially, the plan was to install four brand X active mixers in four tanks, with two side-by-side tanks at each of two locations. However, when an MTM associate at Dark Water Solutions offered (Ixom/Medora) mixers for consideration as an alternate supplier, the city seized the opportunity to conduct a comprehensive comparison.

-

To ensure an unbiased evaluation, the City of Columbus commissioned MTM to supply and install one mixer from each brand at both sites. This parallel testing approach allowed for a direct comparison of the mixers' performance, durability, and operational costs under identical conditions.

-

After a rigorous five-year evaluation period involving continuous use, the results were unequivocal: Ixom/Medora mixers emerged as the undisputed champion. These mixers exhibited unparalleled reliability, demonstrating zero downtime and zero maintenance requirements, in stark contrast to the unreliable performance of brand X mixers.

The combination of uncompromising reliability, minimal maintenance needs, and cost-effectiveness made Ixom/Medora mixers the clear choice for the city's water storage facilities. This decision not only ensured optimal operational efficiency but also maximized the return on investment for taxpayers.

-

The successful implementation of Ixom/Medora mixers serves as a testament to the City of Columbus's commitment to embracing innovative solutions and prioritizing quality over short-term gains. By conducting a thorough evaluation and making an informed decision, the city has set a benchmark for responsible stewardship of public resources. This case study highlights the importance of conducting comprehensive assessments and being open to exploring alternative solutions. By doing so, municipalities can identify and implement cutting-edge technologies that deliver superior performance, reliability, and cost-effectiveness, ultimately benefiting both the community and the environment.

For comprehensive solutions contact MTM and Let’s Innovate.

Design, Manufacturing, Installation

Fremont 2M.G. Rehab & TTHM removal system

MTM collaborated with the City of Fremont, OH, delivering 'Hold Point' inspections during tank rehabilitation and offering a cost-effective remedy for elevated TTHM levels in their 2MG tank. Handling everything from design and engineering to EPA permitting, manufacturing, and installation, MTM provided a comprehensive turn-key solution at a fraction of competitors' costs. Within a week of implementation, the city observed a remarkable 70% reduction in TTHM levels.

Demolition

Erie County Tank Demo

Erie County recently reached out to our team at MTM to safely remove two unused water towers from their system. Our experienced crew efficiently completed the project in just 3 days, demonstrating our expertise in water tower demolition. At MTM, we pride ourselves on delivering comprehensive demolition solutions tailored to the unique needs of each client. Whether you have aging, obsolete water towers or other infrastructure that requires removal, our team has the skills and equipment to get the job done safely and effectively.

Colombia Station Ohio

Ensuring Quality through Rigorous Inspections

In the construction and rehabilitation of critical infrastructure, adherence to specifications and quality assurance are paramount. MTM has established itself as a trusted partner for countless projects, providing comprehensive inspection services that go above and beyond industry norms.

-

MTM's team of skilled professionals brings a wealth of knowledge and experience to every project. Unlike conventional inspectors who may take a passive approach, MTM's inspectors actively engage in the process, demonstrating the ability and determination to access even the most challenging areas.

-

As the Resident Project Representative (RPR), MTM ensures meticulous oversight throughout the construction or rehabilitation process. From new builds to complex renovations, MTM's inspectors meticulously verify that every aspect of the project adheres to the specified requirements, ensuring clients receive the quality they have invested in.

-

MTM's commitment to excellence extends beyond mere compliance. The company's inspectors leverage their extensive expertise to identify potential issues proactively, offering solutions and recommendations that enhance the project's overall quality, efficiency, and longevity.

-

With a proven track record spanning numerous successful projects, MTM has established itself as a trusted partner for municipalities, contractors, and stakeholders alike. By providing uncompromising inspection services, MTM ensures that every project meets the highest standards of quality, safeguarding investments and delivering lasting value.

Tank Mixing

Upgrading Grove City's Passive Mixer

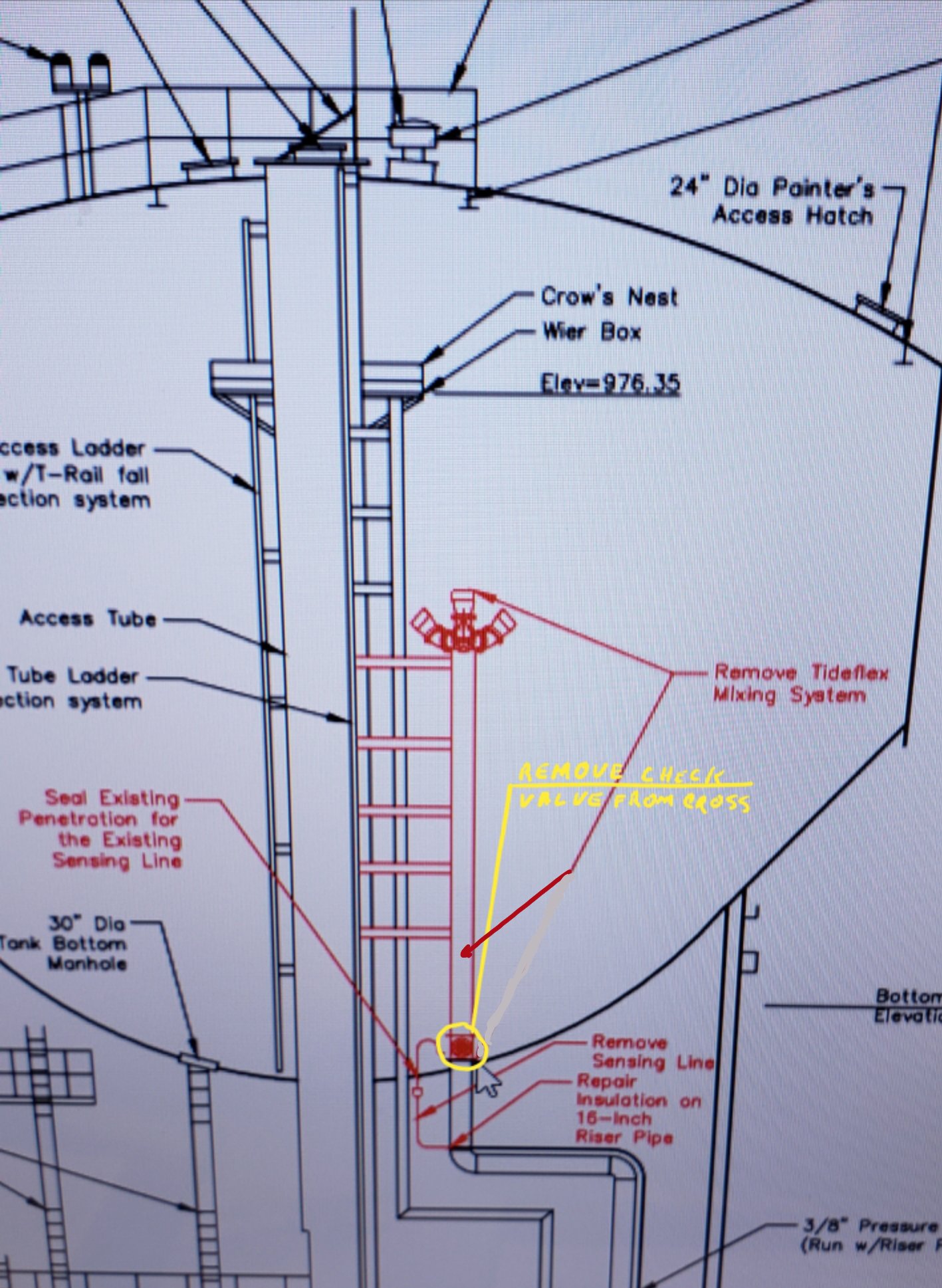

Grove City, Ohio, sought MTM's expertise to enhance their in tank mixing capability by replacing the existing passive mixing system with a more robust active mixer. The project involved removing the existing 16" dia. x 30' long ductile iron mixing system without damaging the interior coatings.

-

With careful Planning, maneuvering and precision, MTM's team successfully extracted the fill line/mixing system without causing any damage. The crane's remarkable reach proved invaluable, as every inch of its 220-foot height was utilized to accomplish the delicate operation flawlessly. By combining strategic planning, specialized equipment, and skilled execution, MTM delivered a solution that met Grove City's requirements while upholding the highest standards of quality and safety.

Tank Mixing Aeration

Comprehensive Solution for the Village of Wellington

As a leading provider of mixing and aeration systems, MTM not only designs and manufactures custom solutions but also collaborates with major industry suppliers. The Village of Wellington entrusted MTM with a comprehensive project, leveraging the company's expertise and diverse capabilities.

-

The Village of Wellington required the supply and installation of two IXOM/Medora SN-10 Floating Mechanical Aeration units, a GS-12 mixer, and a 3-HP ventilation unit. These components were to be integrated into the Village's new 300,000-gallon glass-lined tank.

-

The project presented unique challenges that required MTM's ingenuity and problem-solving skills. Fabricating and attaching ductwork for the ventilation system demanded precision engineering and meticulous execution. Additionally, installing the control panel in the base of an existing adjacent composite tank required careful planning and coordination.

-

MTM's team of skilled professionals seamlessly integrated the IXOM/Medora aeration units, the GS-12 mixer, and the ventilation system into the new glass-lined tank. Their expertise ensured that each component was installed flawlessly, adhering to the highest standards of quality and performance.

-

By leveraging MTM's comprehensive capabilities and collaborating with industry-leading suppliers, the Village of Wellington benefited from a turnkey solution tailored to their specific requirements. This project exemplifies MTM's commitment to delivering exceptional results through trusted partnerships and innovative engineering solutions.